In many industries such as in a chemical plant, it’s often necessary to use pumps to push fluids through pipes for the purposes of commercial production. In such cases, it’s usually very important to make sure that the pumps work as efficiently as possible. Most of them tend to be quite expensive, so this is something that will make your business more profitable.

In order to get this done, you will need to understand the various issues that affect the longevity of any pump, and then make sure that they are optimized for the kind of use you want to put them to. Some of the most important of these include:

Proper installation

When you want a pump in a chemical plant to last long, you have to make sure that it’s properly installed. This usually means making sure that it’s in the right location, and that it’s put in place properly. The latter is particularly important since it determines the conditions in which the pump works. For instance, if it’s a type of pump that tends to vibrate a lot, it might end up undergoing mechanical damage fast if it’s not anchored down. This effect is made worse in instances where the pump has to be used for long.

Getting the right sort of pump

How you choose the pump will also determine how long it lasts. For instance, if you choose a pump that will always work at very close to its limits most of the time, it’s likely to get damaged faster. This means that when you are shopping for one, you should first find out the technical details of what you need the pump to do, and then get one that is slightly overpowered for this role. This way, it’s less likely to suffer from a lot of stress, which usually contributes to quick damage.

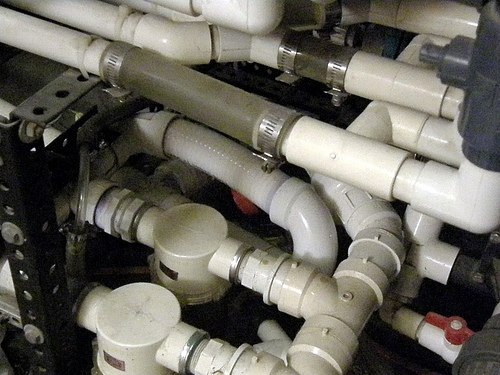

Making sure that all the connections are intact

When you first get the pump, you will need to connect it to pipes in order for it to perform its functions. On the surface, this might seem like a trivial thing, but how you do this has a huge impact on the long term functioning of the pump. For instance, if some of the pipe installations are not done properly, the pump could end up sucking in air together with the fluid it’s supposed to pump. This usually damages the pump to such an extent that you will need to spend a lot of money on repairs in the long term. To avoid this, you have to make sure that everything associated with the pump including the pipes and how they are connected is optimized.

How regularly do you maintain them?

Just like other machines, it’s important to have the pumps checked every once in a while even if they are fully functional. Most manufacturers have some sort of maintenance schedule, and it would be a good idea for you to follow this to make sure that major problems with the pump are avoided.